Across the country, 1-day floor coating companies are saturating the market with flashy claims like: “Our coatings are 4 to 20 times stronger than epoxy!”

But let’s be clear—this isn’t a science-backed comparison to professional-grade garage floor epoxy systems like the ones we install at GarageFloorCoating.com. It’s a clever marketing trick meant to create doubt and push a thinner, faster, and ultimately weaker product.

If you want a floor that lasts—not just one that looks good for a season—understanding the difference matters.

1-Day Companies: They’re Not Talking About Professional Garage Floor Epoxy

These claims don’t compare their coatings to what we use. Instead, they’re stacked against the weakest link: inexpensive, water-based epoxy DIY kits you’d find at a hardware store.

At GarageFloorCoating.com, our garage floor epoxy system is in a different league. Here’s how our multi-layer process compares to the 1-day approach:

What we install:

- A 100%-solids epoxy primer that penetrates concrete and meets ASTM F3010 standards for moisture mitigation

- A full-flake broadcast layer for enhanced durability, traction, and aesthetics

- Two 100%-solids polyaspartic topcoats for chemical, UV, and abrasion resistance

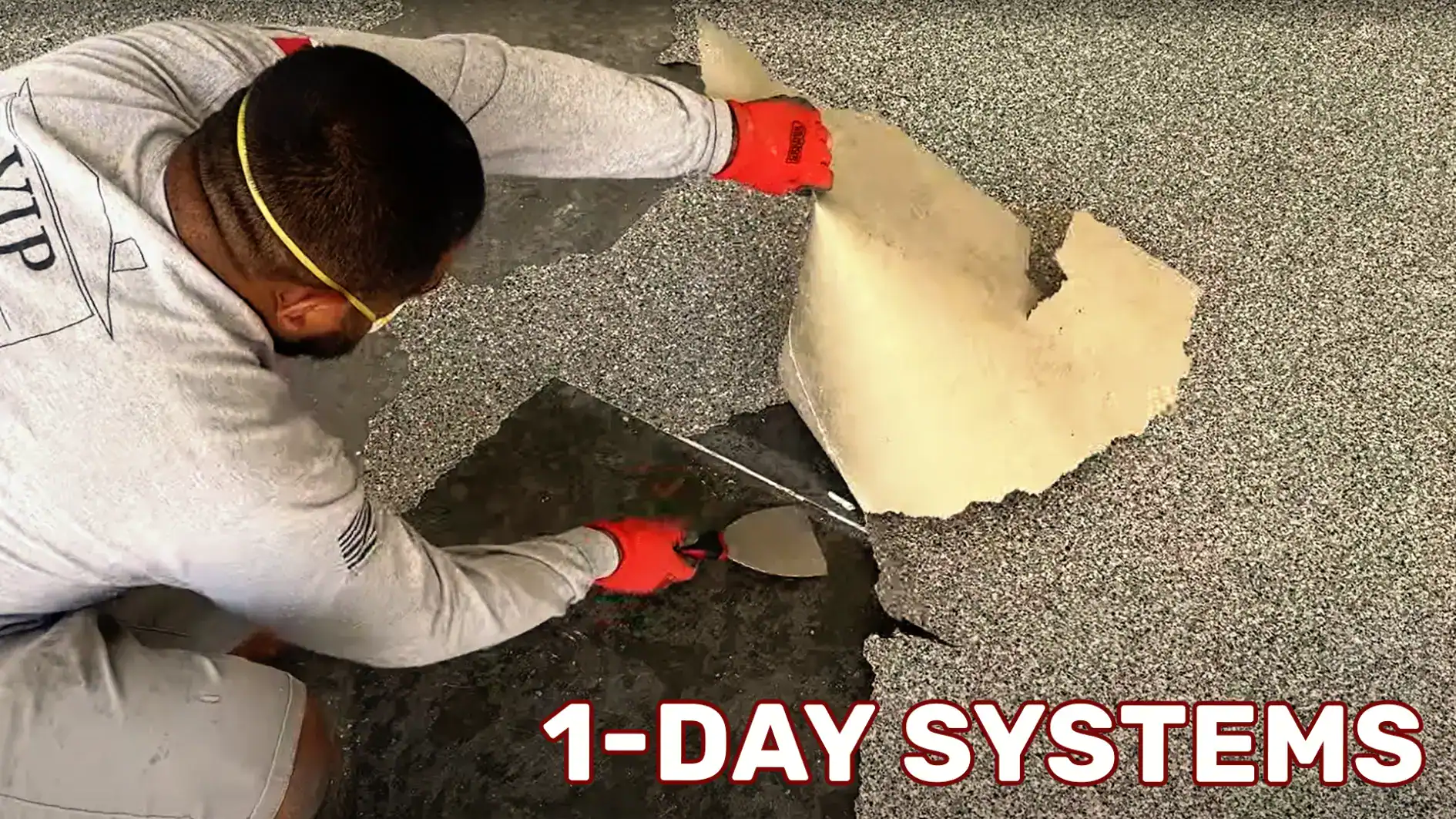

What 1-day companies install:

- A fast-drying polyurea or polyaspartic hybrid applied direct-to-concrete

- One clear topcoat—often less than 100%-solids

- No moisture mitigation

These companies are not comparing apples to apples—they’re comparing apples to fruit snacks.

“Stronger” Means Nothing Without Context

Touting strength without defining the metric is misleading. Are they referencing hardness? Flexibility? Bonding power?

Typically, they’ll highlight one lab metric—like Shore D hardness—and ignore all others. But the performance of a garage floor epoxy system depends on multiple, interlocking factors:

- Adhesion strength, so the coating doesn’t peel

- Moisture mitigation, so vapor doesn’t cause bubbling or delamination

- Thickness, to absorb long-term wear and tear

- Chemical and UV resistance, to preserve the look and integrity

In all of these real-world categories, our epoxy-based system outperforms a rushed, thin 1-day install.

The Moisture Threat: Ignored by 1-Day Systems

Moisture-vapor transmission is a major reason coatings fail—especially when no vapor barrier is in place. Applying polyaspartic or polyurea coatings directly to bare concrete without testing or sealing is risky, regardless of your climate.

At GarageFloorCoating.com, we never skip this step. We begin with thorough slab testing and apply a 100%-solids garage floor epoxy primer that’s engineered for moisture mitigation.

This is what allows us to confidently offer a lifetime warranty against moisture-related coating failure. The 1-day guys? They can’t offer that—because their system simply doesn’t protect against it.

Fast Doesn’t Mean Better—It Means Compromised

The appeal of 1-day systems is speed. But to save time, they cut corners:

- No second topcoat for extra UV or chemical protection

- No full-flake embedment or buffing

- No vapor barrier to ensure long-term adhesion

You may get a fast installation, but it comes at the cost of durability—and peace of mind.

Choose Garage Floor Epoxy That’s Engineered to Last

At GarageFloorCoating.com, we don’t chase speed—we chase performance. Our garage floor epoxy system is built on decades of experience, scientific standards, and proven longevity.

Contact us today for a free consultation and see why our system outlasts the gimmicks. With GarageFloorCoating.com, you’re getting more than a coating—you’re getting a floor built to endure.

About the Author

Share this Post