In the race to offer fast, 1-day garage floor installations, many companies advertise polyaspartic floor coatings as a complete solution. But what they won’t tell you is that industry experts, coating manufacturers, and professional standards organizations overwhelmingly warn against skipping the crucial first step: applying a moisture-mitigating epoxy floor coating primer.

What Happens When You Skip Moisture Mitigation

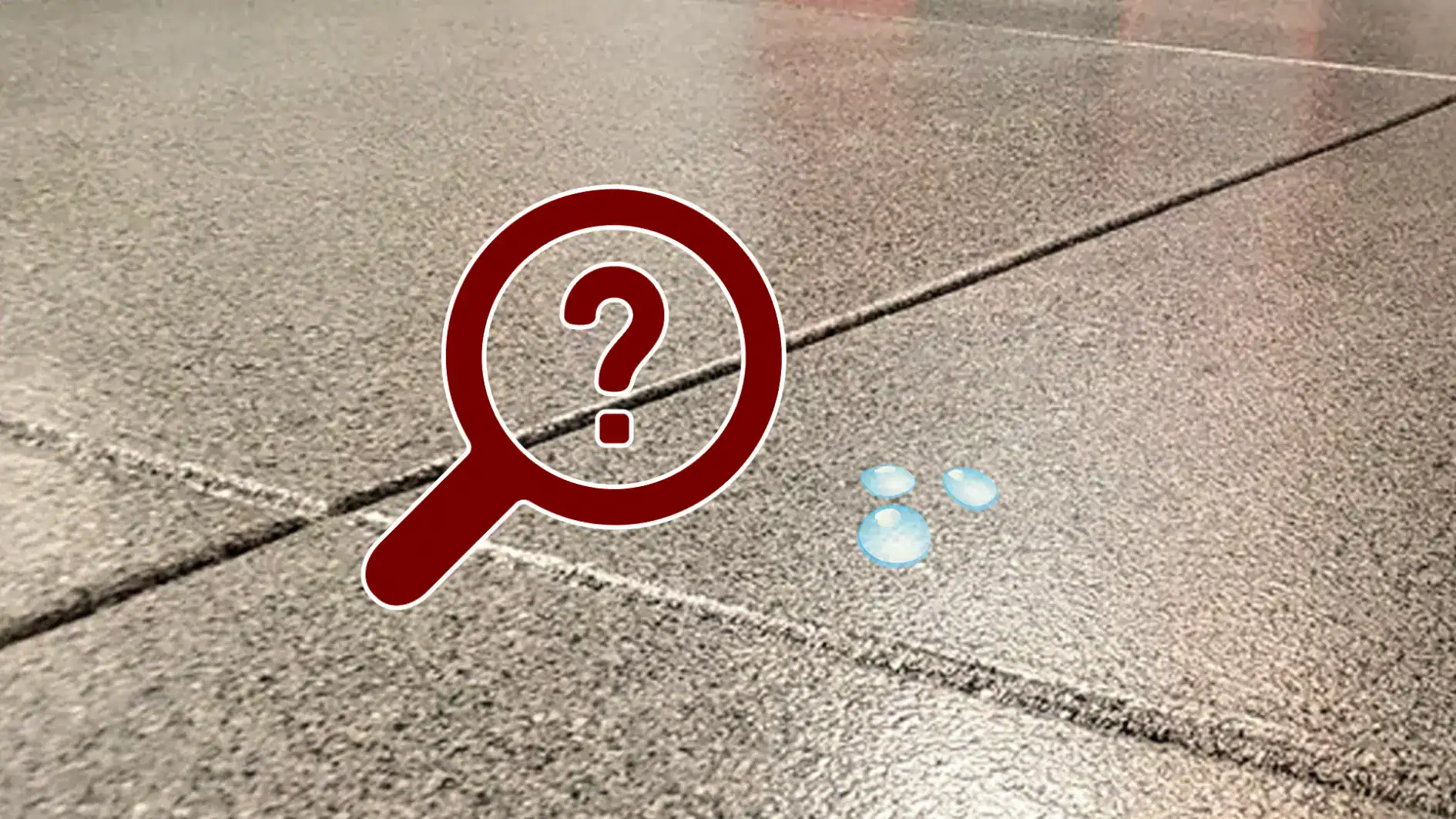

Concrete isn’t dry—even in arid climates. Moisture vapor naturally migrates upward through the slab, especially in garages that sit directly on ground soil. Fast-curing polyaspartic floor coatings don’t penetrate deeply into the concrete. Without a moisture-mitigating coating layer, you risk:

- Trapped moisture vapor causing hydrostatic pressure

- Bubbling, peeling, and delamination

- Voided warranties and expensive repairs

The rapid cure time of polyaspartics makes them excellent topcoats—resistant to UV damage, stains, and impacts—but unsuitable as direct-to-concrete primers.

Industry Leaders Agree: Start with Epoxy

Respected manufacturers like General Polymers (Sherwin-Williams), Sika, Corotech (Benjamin Moore), and Dur-A-Flex all advise against applying polyaspartic or polyurea coatings directly to bare concrete. Instead, they recommend:

- Testing every concrete slab for moisture content

- Preparing the surface to the proper Concrete Surface Profile (CSP)

- Using a 100%-solids epoxy floor coating primer as a moisture barrier

Organizations like ASTM International, ACI, ICRI, and AMPP set clear standards around moisture mitigation in resinous coatings. ASTM F3010 specifically requires a vapor barrier primer beneath impermeable coatings such as polyaspartics and polyurea. Ignoring these steps to rush through a 1-day installation results in early coating failure and a floor that won’t stand the test of time.

Why 1-Day Systems Cut Corners

Companies pushing 1-day garage floor installations promote speed above all else. But the reason they skip epoxy primers isn’t because polyaspartic floor coatings work better—it’s because skipping moisture mitigation saves them labor and time. The result?

- Thin base coats that cure too quickly to bond well with the slab

- Weak adhesion and poor moisture control

- Warranties that exclude moisture-related issues or set unrealistic moisture tolerance limits

These rushed systems often fail within months, leaving homeowners on the hook for costly repairs.

The GarageFloorCoating.com Difference

At GarageFloorCoating.com, we follow the science and the standards. Our 2-day process ensures your floor is built to last:

- Step 1: Moisture Testing. We test every slab to determine moisture content.

- Step 2: Epoxy Primer. We apply a 100%-solids moisture-mitigating epoxy floor coating primer that penetrates deeply into the concrete. This creates a powerful bond while controlling moisture vapor transmission.

- Step 3: Polyaspartic Topcoats. We finish with high-quality polyaspartic floor coatings that deliver superior UV, stain, and impact resistance.

Unlike most 1-day systems, our floors come with a true lifetime warranty that covers moisture-related failures—because we do the job right the first time.

Why Moisture Mitigation Matters Everywhere

Even in dry regions, ground moisture and shifting humidity levels mean concrete is never completely dry. The only way to protect against peeling, blistering, and early coating failure is with a proper moisture-mitigating coating system.

If a company tells you polyaspartic floor coatings can be applied directly to concrete in just one day, think twice. Fast doesn’t mean durable.

Protect Your Floor—and Your Investment

Your garage is more than a place to park your car. It’s a workshop, a gym, a storage hub—and it deserves a floor built for long-term performance.

GarageFloorCoating.com delivers floors that last. Our process follows strict industry standards, respects manufacturer guidelines, and protects your investment for the long haul.

Don’t settle for shortcuts. Choose the experts who back up their work with real science, proven methods, and a lifetime warranty that means something.

Trust GarageFloorCoating.com. Trust the process. Trust a floor that lasts.

About the Author

Share this Post