The promise of a “1-day” garage floor coating sounds appealing. It’s fast, convenient, and out of your way in less than 24 hours. But what homeowners rarely see is how much gets skipped to make that timeline possible. Many of these companies rush through critical steps like moisture testing and vapor barrier application, putting the entire coating system at risk of early failure.

The biggest shortcut? Applying a polyaspartic or polyurea coating directly to concrete without a moisture-mitigating epoxy primer. It saves a few hours during installation but can cost you thousands later in repairs or full replacement.

What the Experts Say

Leading coating manufacturers such as Sherwin-Williams (General Polymers), Sika, Benjamin Moore (Corotech), BASF, Tnemec, Stonhard, Euclid Chemical, and Eco-CorFlex all emphasize the same core principle: always test for moisture and always start with a 100% solids epoxy moisture vapor barrier before applying any polyaspartic or polyurea topcoat.

These fast-curing products don’t absorb into concrete the way epoxies do. When moisture gets trapped beneath them, it creates hydrostatic pressure that leads to bubbling, peeling, and delamination—sometimes within months. Even manufacturers like ArmorPoxy and VersaFlex note that their polyurea and polyaspartic coatings are designed only as topcoats, never as primers.

What Industry Standards Require

Reputable organizations like ASTM International, the American Concrete Institute (ACI), the International Concrete Repair Institute (ICRI), and AMPP (formerly SSPC and NACE) all align on one message: proper preparation matters. Their published standards require moisture testing, concrete surface profiling, and the use of an epoxy-based vapor barrier before applying any fast-curing coatings.

ASTM F3010 specifically defines the requirements for moisture vapor control beneath resinous flooring. Ignoring this standard can void warranties and dramatically shorten a coating’s lifespan.

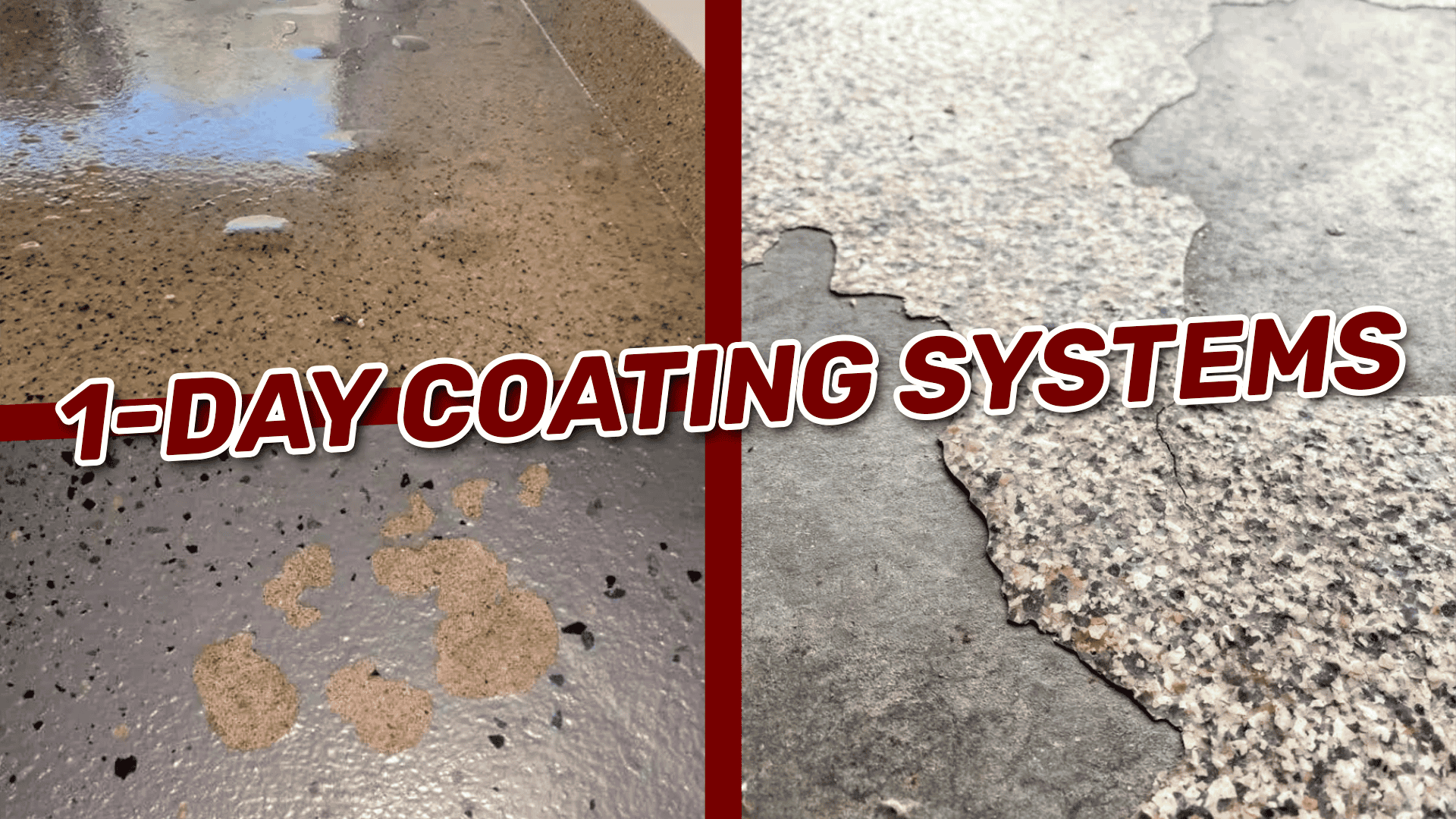

Why “1-Day” Systems Fail

Here’s what happens when a 1-day garage floor coating installer skips the epoxy primer:

- Moisture becomes trapped beneath the coating, building pressure.

- The bond between the coating and concrete weakens.

- The coating eventually blisters, peels, or separates completely.

To make matters worse, most 1-day installers exclude moisture-related issues from their warranties. Even if they claim to cover it, the coverage usually applies only to extremely low Moisture Vapor Emission Rates (MVER)—typically around 3–4 lbs per 1,000 sq ft per 24 hours, or roughly 75–80% relative humidity (RH).

That’s a serious problem, because most garage slabs in the U.S. exceed 5–10 lbs MVER or 85–100% RH, even in drier climates. Without a moisture-mitigating epoxy primer, failure isn’t a matter of if, but when.

The GarageFloorCoating.com Difference

At GarageFloorCoating.com, we never compromise on science or quality. Every project begins with moisture testing to understand your concrete’s condition. We always apply a true moisture vapor barrier epoxy primer—like Eco-CorFlex MME—that can withstand up to 100% RH and 20 lbs MVER or more.

This foundation allows us to offer real warranties that include moisture protection, not exclude it. The result is a stronger bond, a longer-lasting surface, and a flawless finish that performs beautifully year after year.

Don’t Pay the Price for a Fast Job

A fast garage floor coating may look good at first, but skipping the primer guarantees long-term failure. When it comes to protecting your investment, choose expertise over speed.

GarageFloorCoating.com follows industry standards, uses manufacturer-approved systems, and delivers coatings backed by science—not shortcuts. Choose the company that does it right the first time, so your floor looks incredible and stays that way for decades.

About the Author

Share this Post