Concrete always contains moisture. That statement is true in Arizona, Michigan, Florida, Texas… everywhere. However, countless homeowners are told their garage floor coating failed because their slab had “too much moisture.” The real issue isn’t moisture at all. It’s how polyurea systems are being installed in rushed 1-day applications that are never engineered to survive moisture in the first place.

This is where the moisture meter scam begins.

How Polyurea Moisture Testing Becomes a Warranty Trap

Many 1-day polyurea installers lean on vague moisture limits like “3 lbs MVER,” “6 lbs MVER,” or a maximum Tramex meter reading. Albeit, these numbers sound technical, but they aren’t real engineering standards tied to how their systems perform long-term.

Here’s the trick: installers rarely test before installation, document nothing, and never explain that every slab contains moisture. Hence, when the floor eventually bubbles, peels, or delaminates, they return after failure, take a moisture reading directly at the damaged area—where vapor pressure is naturally highest—and use that number to deny the warranty.

The test isn’t protection. It’s a prewritten exit clause.

Why 1-Day Systems Lose the Fight Against Moisture

A 1-day polyurea system is built around speed, not moisture mitigation. These installs rely on polyurea or polyaspartic primers applied directly to concrete, skipping a true moisture-mitigating base coat entirely. Consequently, these fast-curing primers cannot block vapor, equalize slab pressure, or bond reliably through moisture. They cure quickly, look great on day one, and begin failing the moment natural vapor pressure pushes upward—which happens in every concrete slab over time.

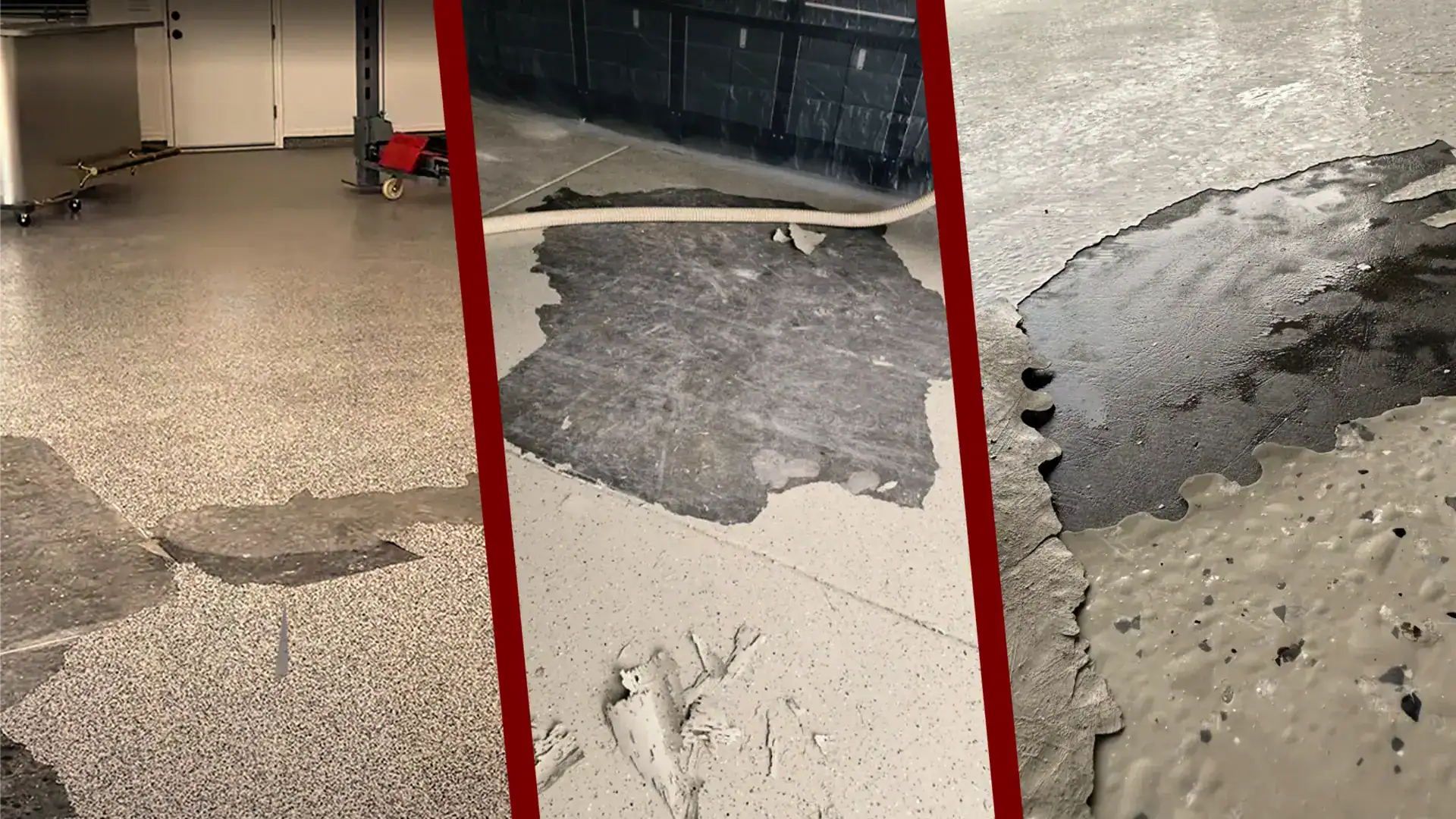

Blistering, peeling, and full delamination aren’t rare outcomes. They’re predictable results of systems that were never designed to handle moisture.

How Our Garage Floor System Is Built for Moisture Mitigation

At GarageFloorCoating.com, we don’t design systems around speed. We design them around chemistry, physics, and longevity.

Our process begins with a 100% solids, moisture-mitigating epoxy primer specifically engineered for moisture mitigation. This layer slowly and deeply penetrates and bonds to the concrete slab. Consequently, it creates a chemically anchored foundation and blocks future vapor transmission, something that fast polyurea primers cannot replicate.

Secondly, we install a decorative flake blend that embeds deeply into that thick stable base (not sitting atop of a thin coat).

Finally, on Day 2, the system is finished with two separate 100%-solids polyaspartic clear coats for abrasion resistance, UV stability, chemical protection, and long-term clarity.

This multi-layer system isn’t rushed into a 1-day window. It’s installed as a professional 2-day process so each layer can do its job correctly.

Quality Takes Time

The pattern is always the same: fast install, no moisture mitigation, predictable failure, then blame the slab. That’s not an accident—it’s the business model.

Contrarily, a properly engineered system acknowledges moisture from the start and builds around it. That’s why we’re able to offer a lifetime warranty that includes moisture, something speed-first polyurea installers simply cannot do.

Before choosing a coating, visualize the difference. Our Live Coatings Visualizer lets you explore colors, flake blends, and finishes designed to perform as well as they look.

If you’re ready for a garage floor coating that’s engineered to last, schedule a consultation with GarageFloorCoating.com today and see what a moisture-mitigating system done right really looks like.

About the Author

Share this Post