The Marketing Trap: Why “Epoxy Flooring” Has Lost Its Meaning

Across the country, garage floor coating companies are advertising “epoxy flooring” in bold letters. But dig into the details, and you’ll often find there’s no epoxy in the system at all. Instead, many 1-day installers use polyurea or polyaspartic-only coatings and refer to them as epoxy—because that’s what customers search for.

At GarageFloorCoating.com, we don’t just use the term. We use the real material. Our nationally proven 2-day system starts with a thick, industrial-grade moisture-mitigating epoxy base coat and finishes with two polyaspartic topcoats. That’s a real epoxy flooring system—and there’s no substitute.

What’s the Difference? Epoxy vs. Polyaspartic as a Base Coat

A polyaspartic is an excellent topcoat. It’s durable, chemical-resistant, and cures quickly. But it was never designed to bond directly with concrete. When companies use polyaspartic (or polyurea) as both the base and top coat, here’s what happens:

- Poor adhesion: Polyaspartic cures too fast to penetrate the concrete deeply.

- Thin foundation: It applies in a thinner layer than epoxy, reducing durability (it is not a “high-build” coating).

- No moisture control: Polyaspartic lacks the properties needed for effective moisture mitigation, especially in humid or high-water-table regions.

On the other hand, 100%-solids, moisture-mitigating epoxy—used as the base coat in our 2-day system—forms a strong chemical bond with the concrete and acts as a moisture-mitigating coating. It’s thicker, more resilient, and better suited to handle vapor pressure and shifting temperatures.

GFC’s 2-Day Epoxy Flooring System: Built to Last

We don’t cut corners. Here’s what sets GFC apart:

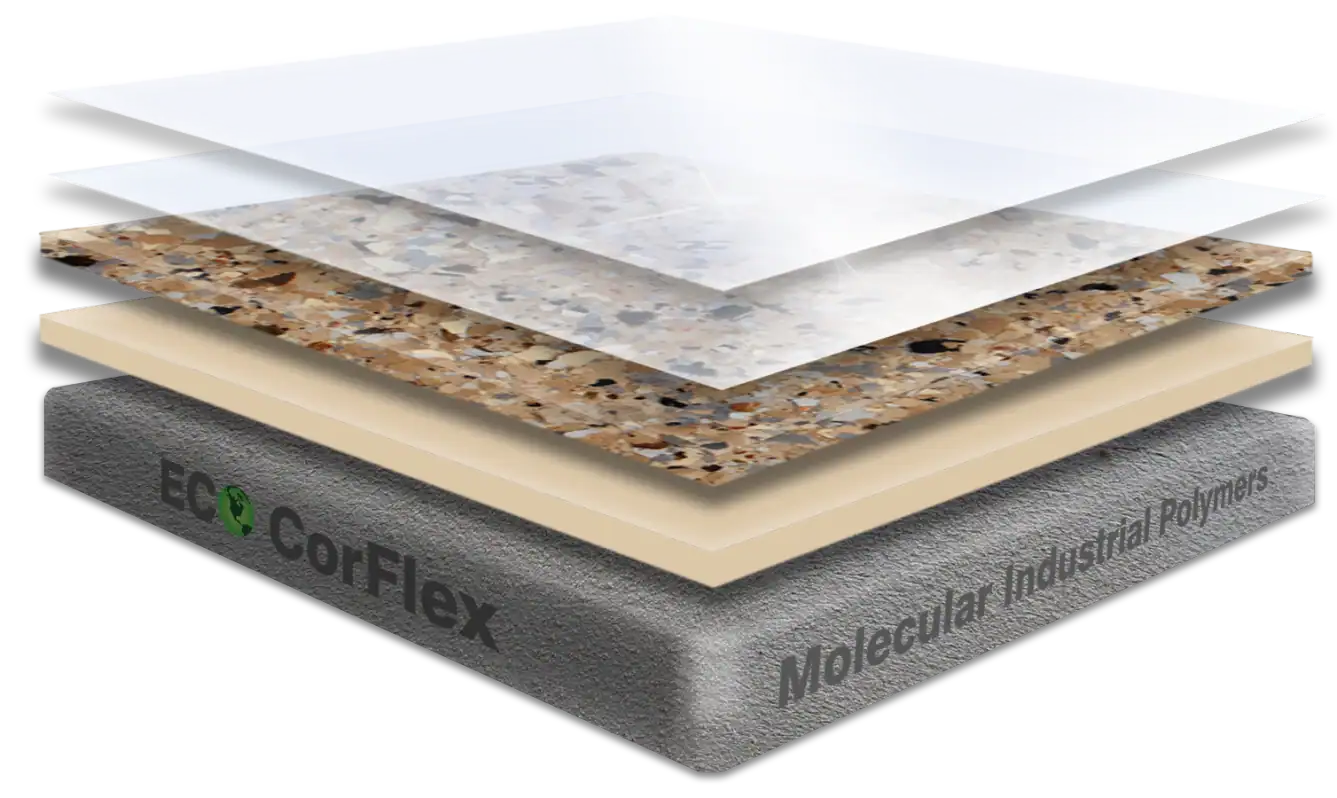

- Day 1: We prep your floor mechanically, then apply a high-build, 100%-solids moisture-mitigating epoxy base coat. It soaks into the concrete surface, cures without shrinking, and delivers unmatched adhesion and moisture mitigation.

- Day 1: We broadcast your selected flake blend into the “wet” base coat.

- Day 2: We apply two 100%-solids polyaspartic topcoats, which protect against UV damage, staining, and abrasion—while giving your floor that beautiful, seamless finish.

This combination delivers a garage floor that’s not only visually stunning but engineered to withstand years of hard use, temperature shifts, moisture, and traffic.

Why “1-Day” Sounds Good—but Falls Short

Speed is a selling point—but it shouldn’t come at the cost of quality. 1-day systems push polyurea-polyaspartic-only coatings to finish quickly. But here’s the tradeoff:

- Fast curing = less bond strength

- Thin coats = reduced durability

- Misleading language = confused homeowners

And while some 1-day installers promise warranties, they often exclude moisture-related failures—a leading cause of floor delamination.

At GFC, we stand by our product. Our warranty covers what others won’t because our floors are built the right way from the ground up.

Don’t Fall for the Word “Epoxy”—Look for the System

Whether you’re in Arizona, Ohio, Texas, or the Northeast, the garage floor coating market is full of big claims. The term “epoxy flooring” has become a catch-all, and unfortunately, that means some homeowners end up with systems that don’t live up to the name.

When you choose GarageFloorCoating.com, you get:

- A true epoxy base coat for superior strength

- A complete, multi-layer system designed for durability

- A moisture-mitigating coating that stands up to weather, wear, and time

- Transparency, quality, and performance you can trust

Contact GarageFloorCoating.com today to schedule your free estimate. Get the real epoxy flooring system—not just the label.

About the Author

Share this Post